Introduction: Why Smart Glasses Quality Control Matters in Production

For B2B buyers of smart eyewear—whether for retail, enterprise, or tech innovation—product quality is non-negotiable. Defects, system errors, or poor finishes can ruin a brand’s reputation.

At Joysee Eyewear, we understand this deeply. As a trusted smart glasses manufacturer in China, our quality control standards are built for global B2B clients who need reliability, performance, and precision in every unit.

In this article, we’ll walk through our smart glasses quality control procedures from raw material inspection to final pre-shipment testing—helping you understand how we ensure every product meets the highest standards.

1. Incoming Material Inspection: Foundation of Quality

Before production begins, we check everything—frame materials, electronic parts, lenses, and packaging supplies.

Key checkpoints include:

Optical lens clarity and thickness measurement

Frame material density, flexibility, and color consistency

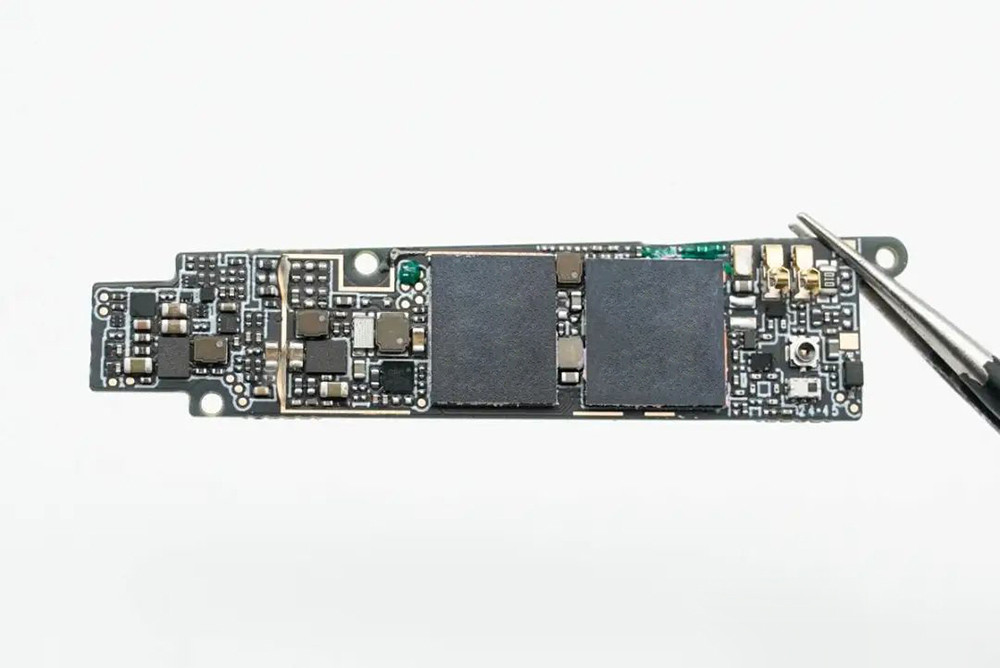

Electronic components like camera modules and chipsets tested for functionality

Battery charge cycles and leakage testing

Each batch is logged with tracking codes and quality status. Materials that don’t meet Joysee’s standards are returned or replaced.

2. In-Process QC During Smart Glasses Production

Smart glasses production requires a combination of traditional eyewear craftsmanship and electronics assembly. Our trained QC staff monitor every step.

Real-time checks include:

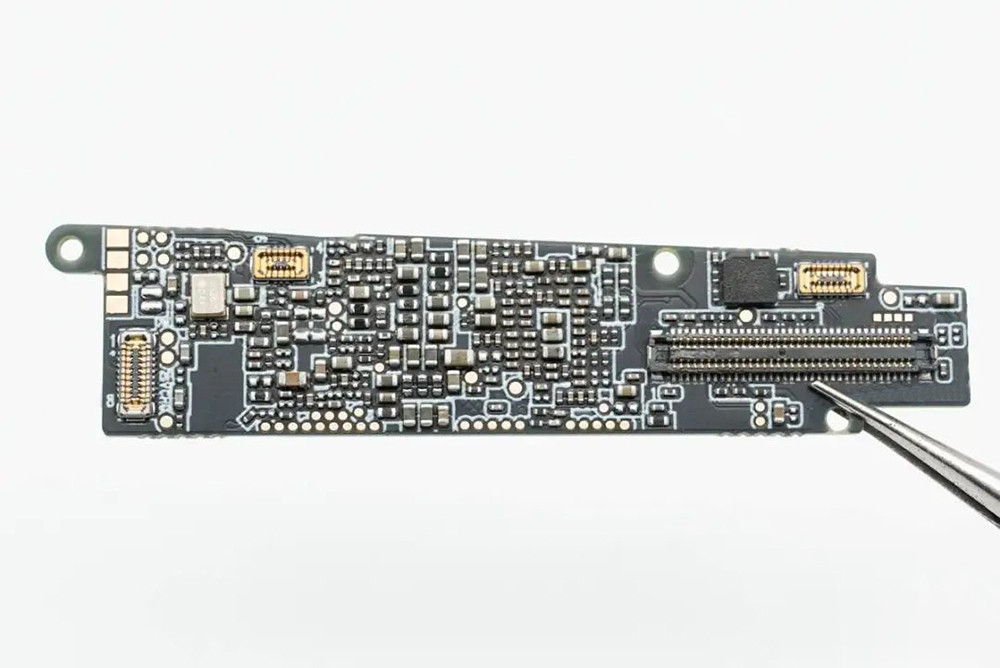

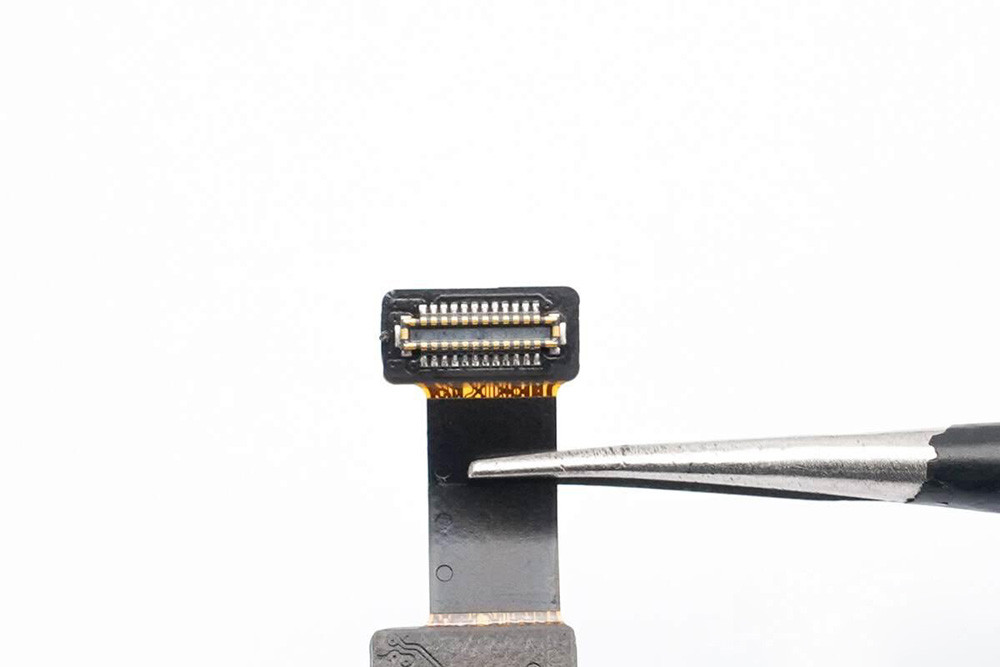

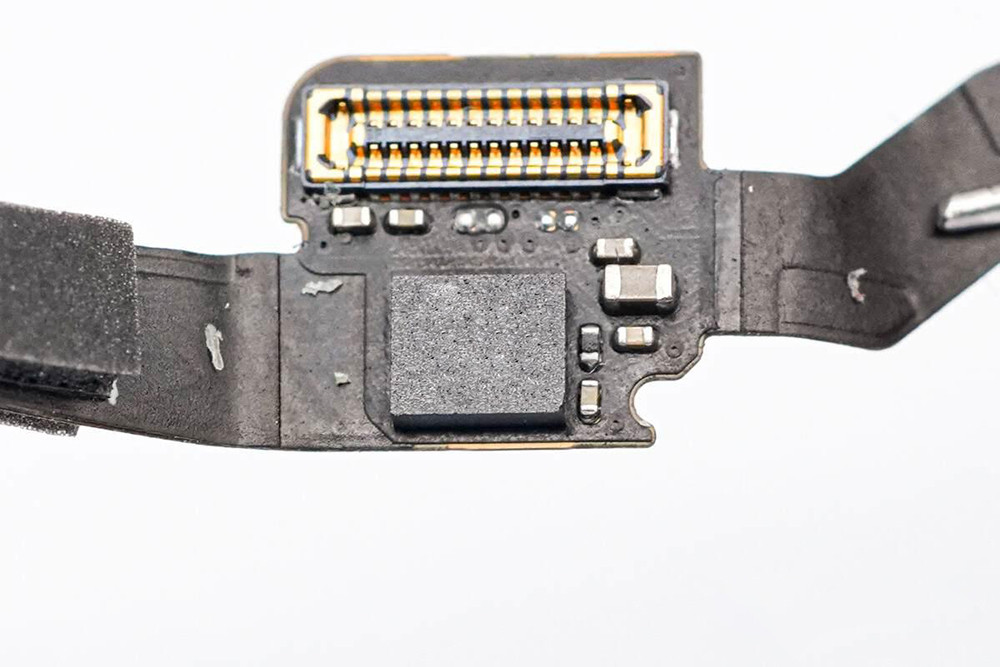

PCB soldering verification under microscope

Lens and camera alignment inspections

Bluetooth/wifi module placement & signal range testing

Frame assembly strength and hinge flexibility

Cleanroom assembly for sensitive electronic modules

QC engineers follow ISO 9001:2015 workflows, using standardized checklists and reporting systems to ensure traceability.

3. Functional Testing: Core Smart Glasses Quality Control Features Check

Once the glasses are assembled, we run a full suite of functionality tests.

Smart glasses quality control tests include:

Camera functionality (photo/video clarity, focus, stabilization)

Microphone and speaker audio checks

Bluetooth pairing and transmission range

AI features, voice command responsiveness, and translation accuracy

App pairing and firmware compatibility

We simulate real-world usage to detect heat issues, connectivity dropouts, or system crashes. Every pair is tested.

4. Smart Glasses Quality Control Aging Test and Stress Testing

Before packaging, a continuous aging test ensures performance under extended use. Units are powered on for 4–6 hours with active features like recording and Bluetooth.

Additional stress tests:

Vibration test (simulating transit conditions)

Drop test from 1.2 meters on hard surface

Sweat, heat, and humidity simulations for user scenarios

Button & touch panel durability (10,000+ taps)

These tests replicate field conditions to ensure your smart eyewear product survives real-world environments.

5. Smart Glasses Quality Control Cosmetic Inspection and Branding Consistency

Even high-tech products need to look good. We check every cosmetic detail to ensure your smart glasses brand is perfectly presented.

Visual inspection covers:

Logo position and clarity

Frame finish (no scratches, bubbles, or paint loss)

Lens cleanliness and polish

Packaging accuracy (manuals, labels, foam, boxes)

Joysee Eyewear’s OEM smart glasses always ship in retail-ready condition, aligned with your brand image.

6. Final QC & Outgoing Inspection Before Shipment

Before packing, our team runs a final random sample QC (AQL standard) and signs off each batch.

Checklist for outgoing inspection includes:

Unit serial number scan & log

Final functionality recheck

Barcode and QR code labeling

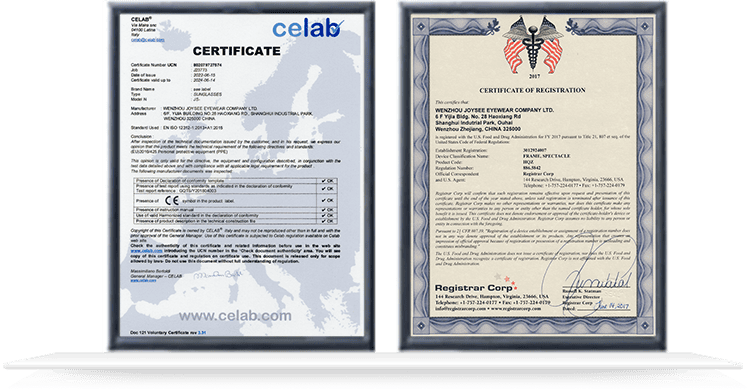

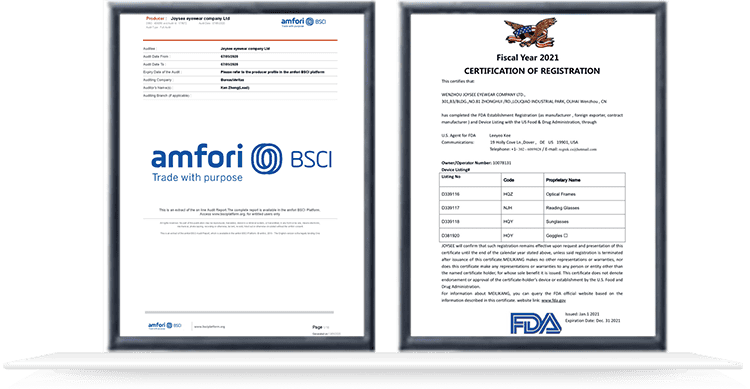

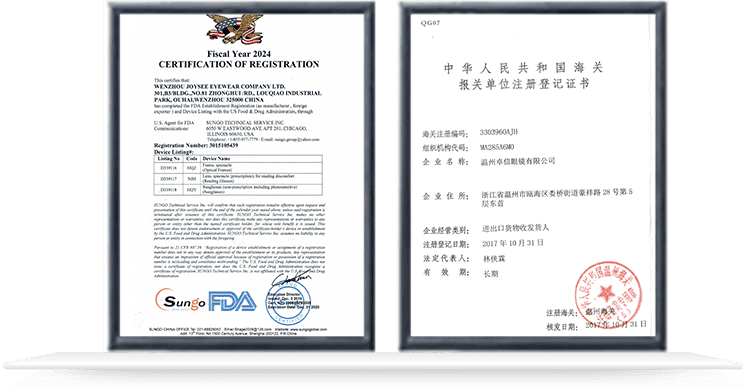

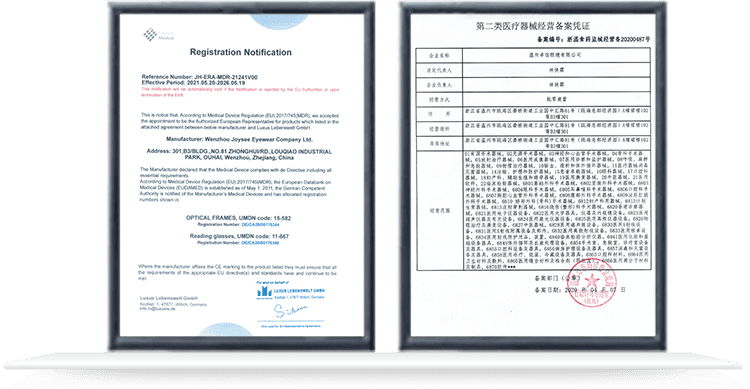

Export documentation & CE/FCC/RoHS certifications

We offer QC reporting with photos/videos on request, so B2B clients worldwide can confirm quality before dispatch.

Why Global B2B Clients Choose Joysee Eyewear

Joysee Eyewear supports brands, startups, and distributors who want more than just a factory—we offer a full-service, quality-first manufacturing experience.

Our B2B production capabilities include:

Low MOQ OEM/ODM for smart glasses

Full QC workflows from materials to shipment

Multilingual project support & documentation

Strict product testing for AI glasses, camera eyewear, AR solutions

Advanced certification-ready lab environment

We work with clients in tech, fashion, health, sports, and logistics who demand professional smart glasses quality control.

Summary: Smart Glasses Quality Control Feature

In the world of smart eyewear, quality control is your brand’s reputation.

Partnering with Joysee Eyewear means gaining a manufacturer that invests in QC, innovation, and long-term trust.

If you’re ready to create smart glasses that your customers can depend on, reach out to our team and request a quote.

📩 Contact Us to Discuss Smart Glasses Production

Smart Glasses Quality Control Suggested Blog Articles:

- Camera Smart Glasses Manufacturers – Trusted Partner in China

Customizing Smart Glasses Features for Different User Scenarios

Smart Glasses Quality Control: How Joysee Eyewear Ensures Superior Smart Eyewear Production

Custom Smart Glasses: Top 5 Customization Services for B2B Brands

ODM vs OEM Smart Glasses With Camera: What’s Right for Your Brand?

How to Choose the Right Smart Glasses Manufacturer for Your Brand – A Complete B2B Guide

- AR and VR Smart Glasses Market Outlook 2025-2034

📩 Ready to Customize Your Smart Glasses? Contact Joysee Eyewear Now